Expression

Expression pedals

When you look for information about making one, you will find a lot less about making one fro scratch. They should be fairly simple, but you will also need information like angle, position, and pedal size. (Size can be big enough for your feet. You’re playing, so it doesn’t matter if it is standard or not.) They are just a big flat paddle connect to a variable resistor and shouldn’t be too hard. I even thought of making mine from scratch.

Generally, you will find that many people: (1) buy a volume pedal for other instruments and use it either as-is or modify it (2) buy an organ expression pedal off eBay and modify it (3) build one from scratch or (4) buy an organ swell pedal that is meant to be used with an electronic organ. None of these have MIDI connectivity.

Angle

The Swell and Crescendo pedals should go from about 41 to 63 degrees (Ref: Perterson) That 22 degrees will need to vary the output in a linear fashion to make it usable on the console. Variable resisters (pots) can be linear or audio (also called logarithmic). Linear means it alters at the same rate as you move change the position: 10% change means 10% difference and 80% change means 80% difference. Audio pots give you different values as you rotate it: 10% might mean 1% change, 50% might give you 10% change in output. You do not want audio pots for your pedal.

Size

Peterson didn’t give a size, so I searched other websites. Organparts offers some information on their shoes and they seem to be sized 280mm x 120mm (or 11" x 4 3/4").

Do-it-yourself

I actually did consider making mine from some pre-cut wood for the shoe then some hinges and variable resistors. How to connect an angular motion to a pot has a lot of different solutions. Some of them are rather clever.

Using string, a gas pedal and a linear sliding pot

An interesting idea that looks simple. You could substitute a nice piece of wood for the gas pedal and have something that looks like an organ expression pedal. String does break (and stretch) but most people don’t “pump” the expression pedals on the organ so it would probably degrade before it breaks.

|

|

Using pipe-fittings. No variable pot fitted.

This idea uses pipe fittings to create a rotation point for the pedal. The information doesn’t include the author’s connection to the variable pot, but either linear (as in the string method above) or a rotating pot could be used with appropriate conversion.

|

|

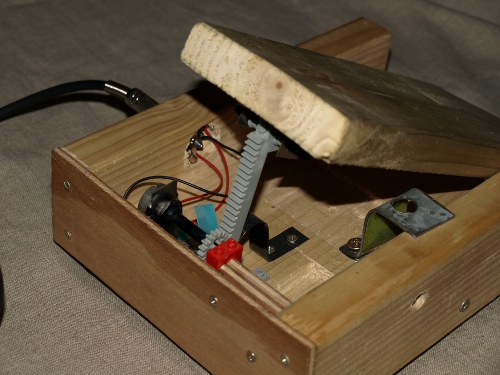

Use Lego to convert angular pedal motion to rotary

I ran across this and thought it was an interesting idea with parts readily available. With wood, a potentiometer and time, I could probably put one of these together. I didn’t, but someone else might think it an ideal solution. To vary how much pressure you need to push the pedal, you will need to add some adjustable friction or hinge.

Commercial pedals

John’s organ recommendations

John’s organ works lists a number of pedals - what they are like I don’t know. The angle may be too low or they may be perfect. The potentiometer on some are not the generally recommended 10K that I’ve read.

Viscount

If you have read my pedalboard section you’ll see I’ve listed Organparts and Viscount. I found the Viscount expression pedals (Viscount MIDI Schweller Pedale) available at Thomman, though I had to write to them for a price. They are normally sold with pedalboards and I’m not sure if they still carry them.

The price was a bit higher than I wanted to pay but I knew they would work and I’d already seem them on their pedalboards. Thomman has a money back guarantee so I took a chance. They arrived and are a mix of plastic and metal. They are fairly sturdy and come with some decent mounting screws - again, for use with the Viscount pedalboards.

A warning: these do not go from 0% resistants to 100%, they are more like 10% to 100%. If you put 5 volts across the pot you will get 0 volts to about 4.5 volts. You will need to compensate in software and that has a bit of a problem. I wrote several people that design encoder boards with analogue input for expression pedals and they all expect 0-5V. My Viscount Cantorum Duo can compensate and I coded the program for pedals to be self-adjusting. You would only need “pump” the pedal from closed to open to have it remember and store the values in EPROM.

Front view of Viscount pedals.

View of the Viscount hinge. You can tighten the pedal down by tightening the screw. There is a ‘friction’ pad and a spring that helps keep the pedal in place.

Rear view of the expression pedals. You can clearly see the compression arrangement for friction.

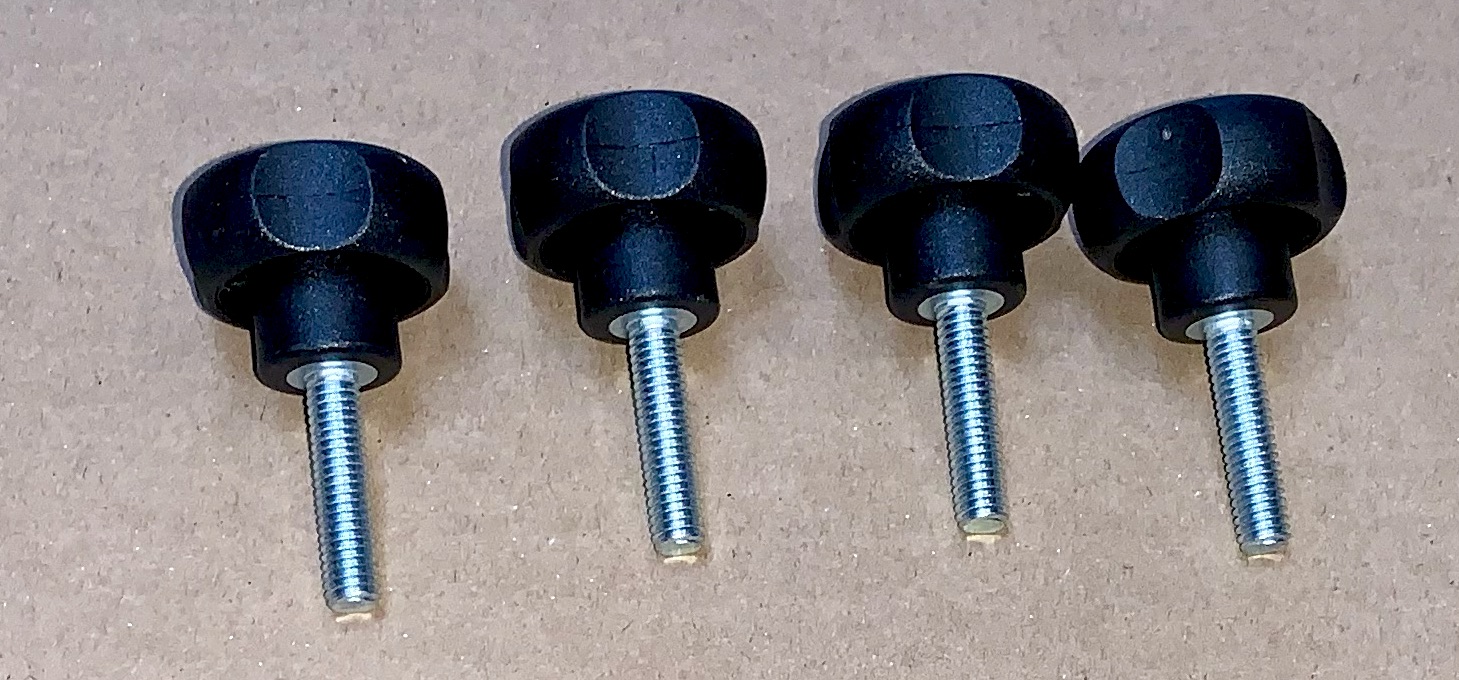

The 4 screws included to hold the expression pedals onto the Viscount pedalboards.

My impression: these are OK pedals. They do the job, I can live with the non-100% resistance, and they are wired and ready-to-go. The price I paid (£215 or £107.50/pedal) is higher than if I did it my self or chose another solution. These feel like organ pedals, work well and I got them working minutes after plugging them in. I’m not disappointed in them, so feel it was the right decision for me.